Welcome to Zhongjda Industry

Toggle Navigation

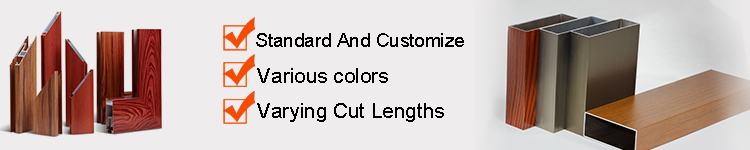

Aluminum can replace wood in a variety of projects. Doors, windows, cabinets and the exterior decoration of the building can all have a wooden look. So how do extrusion manufacturers create this pleasing wood effect on aluminum profiles?

There are two successive processes used to create the look, powder coatings-one of the most common aluminum coatings.

Sublimation-for embossing patterns after powder coating. After completing these processes, you can now replace wood, giving you all the advantages of aluminum profiles.

We will discuss these processes in more detail below

Two processes for creating wood grain effects:

As mentioned above, the manufacturer extrudes through two consecutive processes to produce wood texture-powder coating and sublimation.

Step 1: Powder coating: Aluminum is primed before curing.

The powder coating process can be divided into three steps:

1. Undercoating-Manufacturers apply powder undercoating to aluminum profiles. The powder is electrostatically charged to enhance adhesion.

2. Curing-Place the profile in a curing oven. They are usually left in the oven for about 10 minutes at a temperature of about 200 degrees Celsius.

3. Cooling-Remove the profile from the curing oven and cool it. After they have completely cooled, they can be sublimated.

The second process: sublimation

The sublimation process includes four main steps:

1. Film wrap-a film with a decorative pattern (in this case, wood grain) is wrapped on an aluminum profile.

2. Remove air-remove all air from the space between the film and the profile. In this way, the film can closely adhere to the aluminized film.

3. Curing-Put the wrapped extrudate into the curing oven. As they heat up, the wood grain pattern is transferred from the film to the aluminum.

4. Cooling-Pull the extrudate out of the oven and remove the film. At this point, the pattern has been completely transferred to the aluminum profile. They were allowed to calm down.

5. After powder coating and sublimation, the extrudate can now be transported.

Integrate aluminum profiles into your project. Aluminum profiles can be designed into complex interlocking shapes. The wood effect gives them a beautiful natural look. Now you can design products that look beautiful, natural and have all the benefits of aluminum.