Welcome to Zhongjda Industry

Toggle Navigation

What Are The Benefits Of Considering A Custom Extrusion For Your Next Design Application?

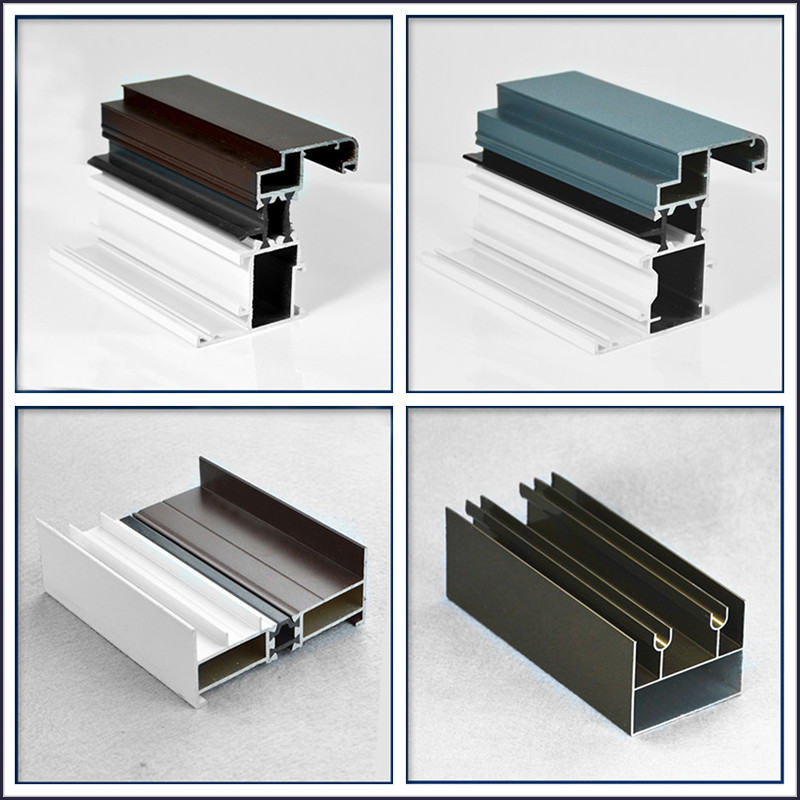

Aluminum is a material that offers a great number of benefits to manufacturers and designers, thanks to its tremendous versatility and other unique properties. And while this versatility makes it feasible for those who work with aluminum to fashion the parts and products they need on site, many manufacturers have found that ordering custom extrusions offers considerable advantages. When you partner with Zhongjda Industry, we’ll deliver your aluminum extrusions to the exact specifications you require, helping to save you time, labor, and money.

What Is An Extrusion?

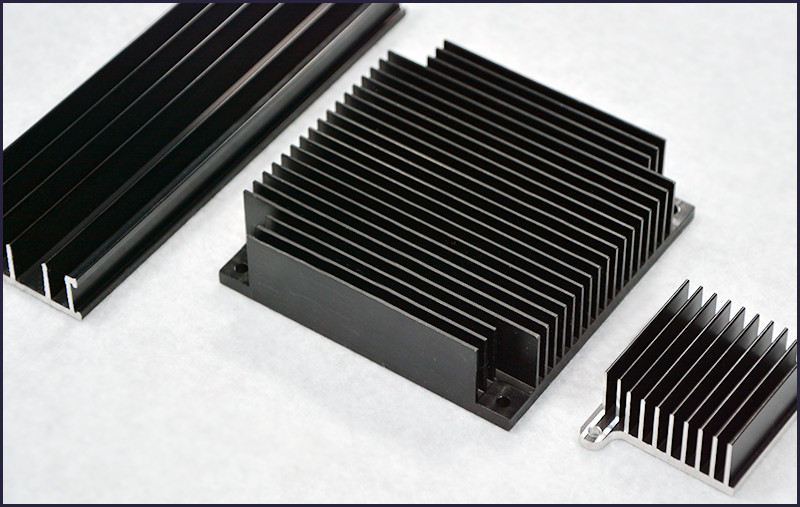

The extrusion process forms objects by pushing material, such as aluminum, through a pre-made mold in order to produce products of a particular shape. The best way to describe it is that it is similar to pushing toothpaste through the end of the tube. Extrusion has a number of virtues. Most importantly, it’s possible to make very complicated cross-sections that would otherwise be highly impractical. Furthermore, you can employ brittle materials and alloys, as the process only applies compressive and shear stresses to the metal.

When using extrusion, the resulting pieces may be as long as necessary. In addition to aluminum and stainless steel, many other materials are extruded on a frequent basis, including other metals, plastics, ceramics, and even concrete. It’s even possible for the extrusion process to strengthen the metal.

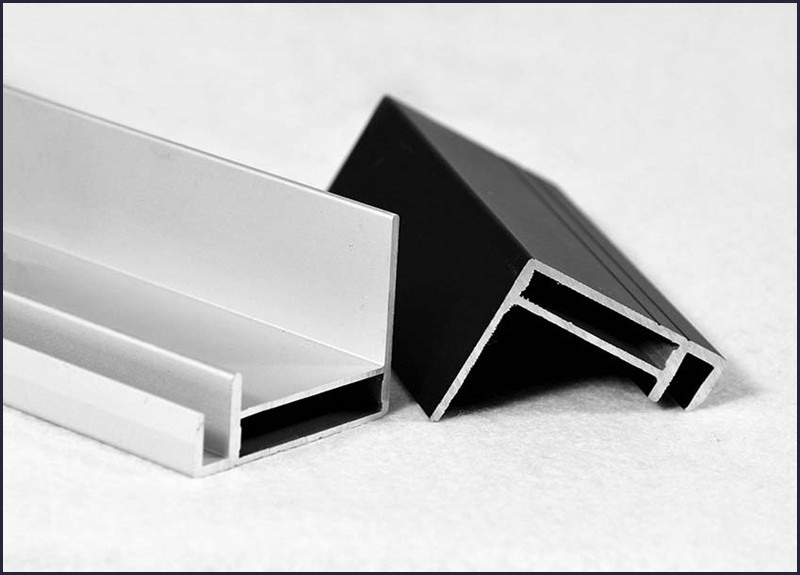

Complicated shapes are viable, including a hollow center, which is known as hole flanging. However, these cavities cannot be made with a simple flat extrusion die, as there is no way to support the center barrier in a way that would allow the material to flow through the die. The die instead has a shape profile that supports the central section, and that shape internally changes along the length of the die. As the material is pushed through, it flows around the support pieces and fuses together on the other side.

What Are The Advantages of Aluminum Extrusion?

Many materials can be extruded, as already mentioned, but few options can match aluminum for its many advantages. First of all, aluminum is about a third the density of steel. That’s why aluminum is so desirable for industries that prize a lightweight, such as aerospace and automotive. Because an extrusion can fit materials to exact specifications, without any excess metal being required, the overall weight can be reduced even further than when misshaped parts are used.

But despite being so low density and lightweight, aluminum still retains an amazing strength-to-weight ratio. For just one comparison, 6061-T6 grade aluminum is almost four times as strong as 304 stainless steel. And as pointed out already, the extrusion process can make the aluminum even stronger.

The strength of aluminum does not come at the cost of machinability. It’s actually pretty easy to take long extrusions and cut them to the desired lengths without any special cutting tools, an important consideration for many manufacturers. Other benefits include aluminum’s excellent weldability, sleek appearance, extended durability, and non-magnetic nature.

Of course, aluminum’s greatest characteristic may be its resistance to corrosion. The aluminum oxide layer that forms on the surface will protect the metal and ensure that it can withstand most hostile environments. Adding to its appeal, if the surface of the aluminum is damaged, the oxide layer will actually repair itself.

Why Is Aluminum So Well Suited For Custom Extrusions?

In addition to all of the above-listed benefits, there are some further reasons to customize your aluminum extrusion. First of all, while aluminum possesses a natural resistance to corrosion, there are certain scenarios in which the metal is actually quite susceptible, for instance in marine environments.

In particular, when aluminum is used in conjunction with another metal, what is known as galvanic corrosion can take place. Because an electrolytic bridge will form when two different metals come into contact, and because it will affect the least noble metal (usually aluminum), aluminum is therefore quite susceptible to galvanic corrosion. However, understanding this is the case, a smart manufacturer will customize their extrusion design to ensure that the risk of galvanic corrosion is minimized as much as possible.

Aluminum is also one of the most malleable metals used regularly in heavy industry. This makes it extremely simple to extrude, allowing for greater versatility. When it comes to custom shapes, aluminum is easier to work with than steel for instance. This ease of use also translates into greater savings.

How to Choose an Aluminum Alloy for a Custom Extrusion?

When it comes time to select your alloy, you may be overwhelmed by all of the many options. Aluminum’s tremendous versatility means there are a wide variety of alloys to choose from, each with a very precise set of properties. Manufacturers need to do their homework before selecting an alloy, and Zhongjda’s experienced service technicians can help with that.

The first consideration should always be performance. What will the extruded part be used for, and what are the required properties. Will it be in a corrosive environment? Will the part be load bearing? Is weight an important factor? Know exactly what you need from the metal, and select the alloy that best matches your specifications.

Next, you’ll need to know how long the fabricated part needs to last. Obviously, the longer lasting alloys will cost more, but that’s to be expected. Again, knowing the type of environment the extrusion will be exposed to will go a long way to determining the durability properties that are necessary.

Finally, cost will always be a primary factor in whatever material you choose. But keep in mind, while it might be tempting to cut corners in order to save money, you’ll likely be sacrificing the durability and/or other properties that you identified in the above steps. While you might save something at the outset, in the long run, not having the right alloy can end up costing you more by sacrificing the longevity of the product.

Summary

With our extensive experience in custom aluminum extrusions and our commitment to supporting our customers, Zhongjda Industry can help you overcome even the most difficult design challenges. Contact us today to find out more about our custom extrusion options.